Water. Dust. Vibration. Every cable faces invisible threats daily.

Most insulation hides protection under opaque colors — but sometimes, seeing is believing.

Clear heat shrink tubing lets you see your protection in action — no guesswork, no hidden issues. It’s the perfect balance of visibility and performance, transforming ordinary insulation into a transparent armor that builds confidence and reliability.

Whether you’re improving traceability on production lines or protecting outdoor cable joints from moisture, clear tubing turns simple wiring into a professional, verified connection.

Expert Sight: What Is Clear Heat Shrink Tubing?

Clear heat shrink tubing is made from cross-linked polyolefin, engineered for both insulation and visibility. When heated, it contracts around wires and terminals to form a durable, transparent barrier.

In its adhesive-lined (dual-wall) version, a hot-melt inner layer forms a watertight seal, providing visual access and complete environmental protection.

Key Technical Specs:

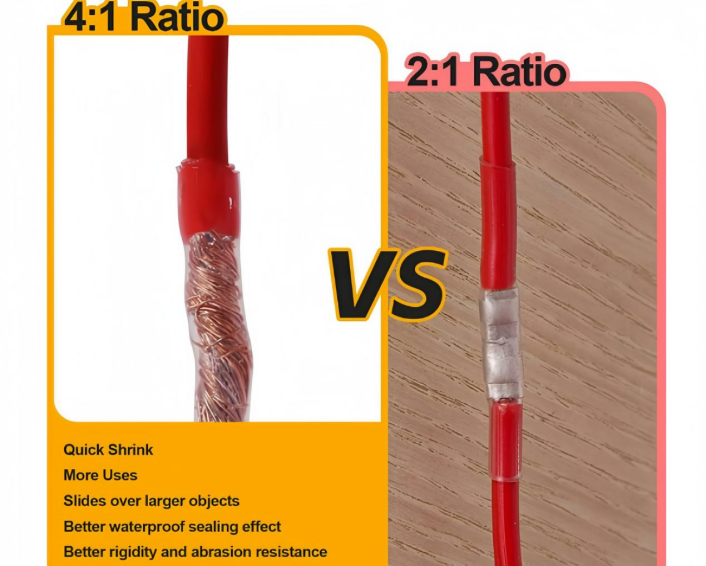

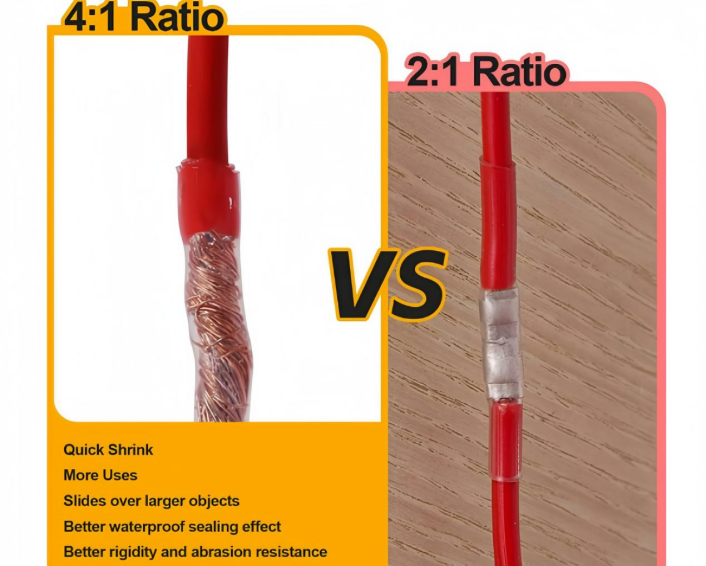

Shrink ratios: 2:1, 3:1, and 4:1

Operating temperature: –55°C to +125°C

Certifications: ISO Certified, UL 224, RoHS compliant

This clarity isn’t just cosmetic — it allows early detection of corrosion, incomplete seals, or poor solder joints during inspection.

Water-Resistant vs. Waterproof: What’s the Difference?

Single-wall clear tubing offers insulation and abrasion resistance — ideal for indoor use or bundling.

Dual-wall clear tubing (adhesive-lined) delivers a watertight, vibration-resistant seal, perfect for marine or outdoor applications.

Independent immersion tests show properly installed dual-wall tubing maintains full seal integrity after 48+ hours of water exposure, making it reliable in the harshest conditions.

Choosing the Right Size and Shrink Ratio

Selecting the correct tubing ensures a secure and long-lasting seal.

Shrink Ratio | Application | Recommended Use |

2:1 | Standard insulation | Consistent wire sizes, general-purpose bundling |

3:1 | Flexible sealing | Irregular connectors, maintenance or rework |

4:1 | Heavy-duty sealing | Automotive, marine, outdoor junctions |

Typical diameters range from 1.6 mm to 50 mm, all UL- and RoHS-compliant.

Pro tip: Choose a tubing with an internal diameter 20–30% larger than the largest object before shrinking for best fit.

Main Features and Benefits of Clear Heat Shrink Tubing

1, Full Transparency for Easy Inspection

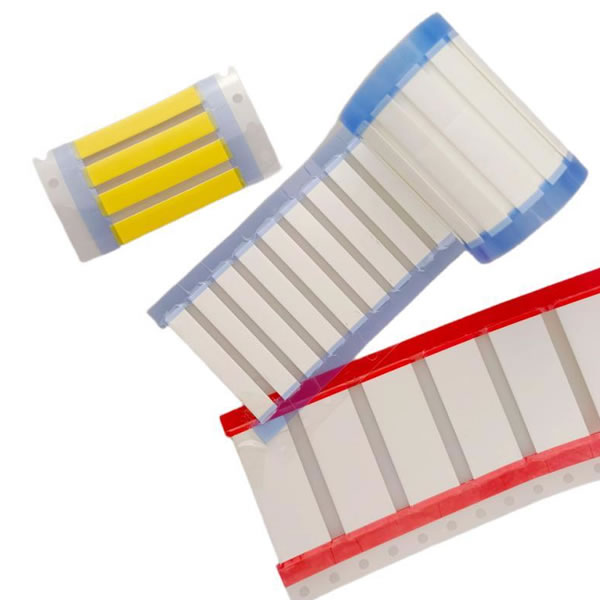

Clear tubing lets you see labels, wire colors, and connections without removal — perfect for quick checks, maintenance, and safety audits.

2, Reliable Electrical Insulation

Despite its clarity, it offers strong dielectric protection, preventing short circuits and ensuring stable performance under continuous electrical load.

3, Waterproof and Chemical-Resistant

With an adhesive lining, it seals out water, oil, and salt spray — ideal for marine, automotive, and outdoor systems.

4, Durable Strain Relief

It shrinks tightly around joints and connectors, reducing vibration stress and improving cable longevity in demanding environments.

5, Clean, Professional Appearance

The transparent finish keeps markings and serial numbers visible, supporting traceability and a neat, high-quality look.

Practical Applications of Clear Heat Shrink Tubing

In the automotive industry, clear tubing seals and identifies wiring harnesses in engine compartments, allowing quick color-code checks without disassembly.

In electronics manufacturing, small-diameter tubing protects solder joints, thermistors, and sensor leads — technicians can instantly verify every connection.

In marine systems, dual-wall clear tubing prevents saltwater corrosion while keeping terminals visible for routine inspection.

In renewable energy systems, such as solar installations, it shields outdoor junctions from UV and moisture while preserving connection integrity.

Across industries, transparency means confidence — ensuring long-term reliability, easier maintenance, and professional assurance for every B2B project.

Frequently Asked Questions

1. Is clear heat shrink tubing as durable as colored tubing?

Yes. Premium polyolefin clear tubing provides the same insulation and mechanical strength as colored options — only the visibility differs.

2. Can clear tubing turn yellow over time?

Low-quality PVC can discolor under UV exposure, but high-grade UV-stabilized polyolefin remains clear and stable outdoors.

3. What’s the difference between single-wall and dual-wall types?

Single-wall = insulation and flexibility. Dual-wall = insulation + hot-melt adhesive for waterproof sealing.

4. How do I choose the right size?

Select a size 20–30% larger than your connector before shrinking.

5. Where to buy clear heat shrink tubing with consistent quality?

Always source directly from ISO- and RoHS-certified manufacturers. Factory-direct suppliers like JS Tubing provide traceable quality, technical support, and custom shrink ratios.

Why Choose JS Tubing

At JS Tubing, we’ve spent over a decade helping global OEMs and distributors design reliable cable protection systems for automotive, marine, and industrial environments.

With ISO certification, RoHS compliance, and full material traceability, we ensure every product meets strict international standards — from small-batch samples to large-scale production.

Every connection matters — make yours transparent, sealed, and secure.

Conclusion & Call to Action

In today’s complex electrical world, visibility means control. Clear heat shrink tubing delivers more than protection — it builds trust into every connection.

By combining insulation, sealing, and inspection visibility, it ensures long-term performance, safety, and professional quality.

Discover the power of transparency.

Explore our full range of clear heat shrink tubing or contact JS Tubing for free samples and a tailored quotation — and see your connections protected, sealed, and visible like never before.